CNC Machining Services for Custom Parts

Our advanced milling centers and turning equipment deliver precision with tolerances as tight as 0.001 inches. Beyond standard machining, we provide value-added services like CNC routing, EDM machining, and precision grinding, perfect for designers and product developers seeking to actualize innovative ideas with top-quality custom components. Whether the project is straightforward or complex, our equipped machine shops are ready to take it on. We guarantee not only superior quality but also rapid delivery—custom simple machined parts are shipped within just 1 day. Get started.

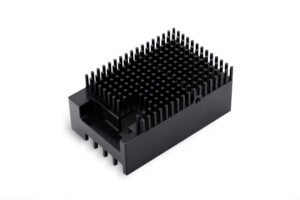

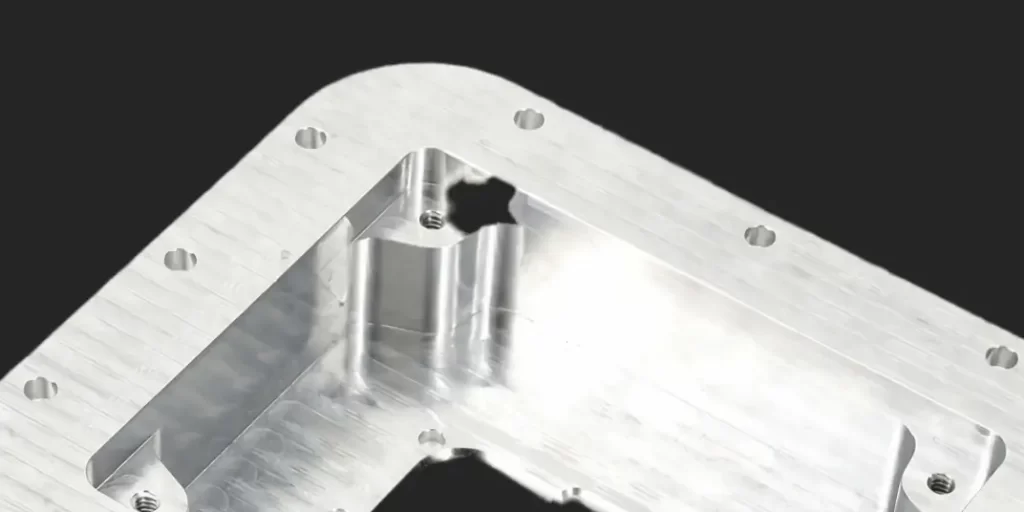

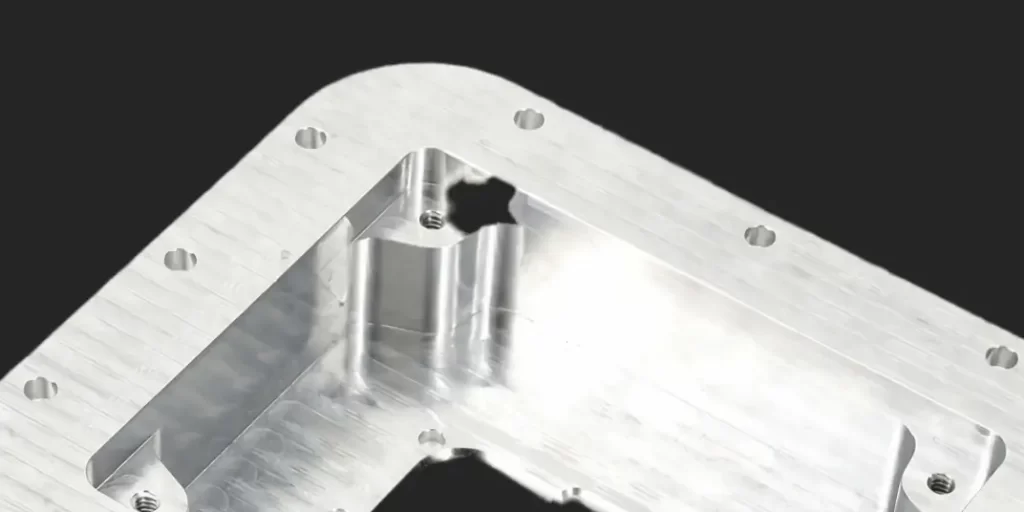

Custom CNC Milling Services

CNC milling employs multi-axis operations, such as 3, 4, and 5-axis machining, to ensure precision and intricate geometries from blocks of metal or plastic, efficiently producing complex parts.

Custom CNC Turning Services

CNC turning uses CNC lathes and turning centers to shape metal rob stock, focusing primarily on cylindrical turned parts. Ensure components achieve consistent dimensions and smooth finishes.

CNC Machining Materials

Metals

Aluminum is lightweight yet strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive parts.

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

Plastics

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

ABS Beige(Natural)

ABS Black

ABS Black Antistatic

ABS Milky White

ABS+PC Black

ABS+PC White

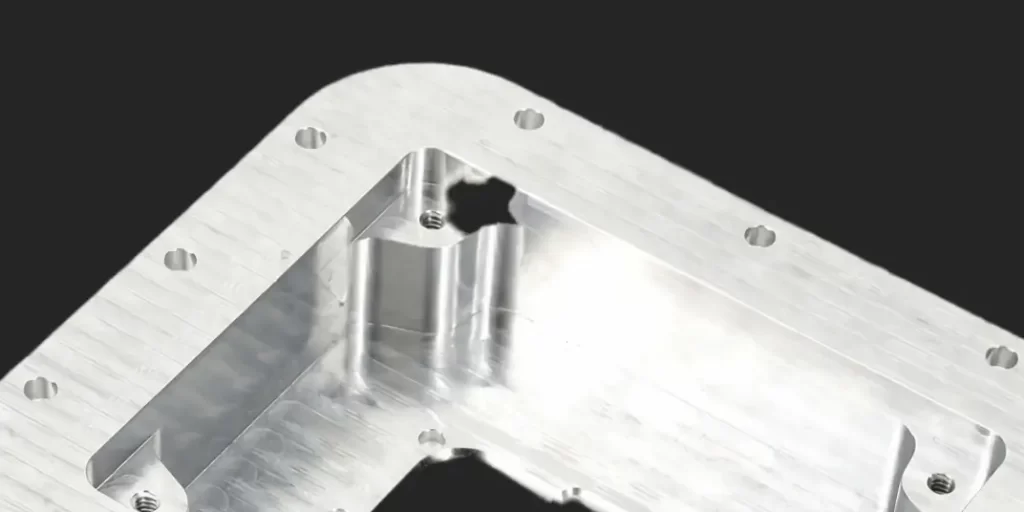

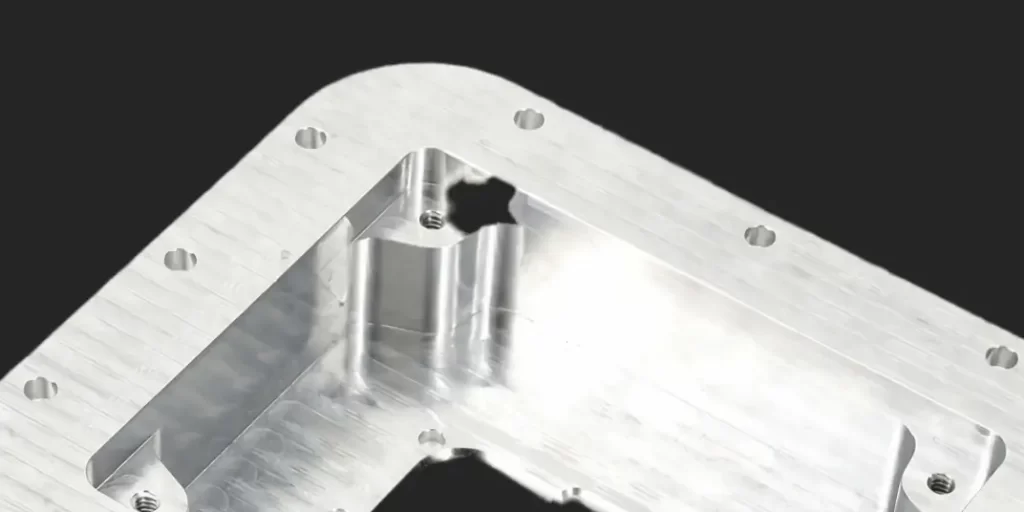

CNC Machining Surface Finishes

Achieve the perfect finish with our range of surface treatments. Whether you require anodizing, plating, or painting, we ensure your parts meet both aesthetic and functional specifications.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Tolerances for CNC Machining

Our CNC machines operate with precision tolerances that meet industry standards, ensuring that every part is consistently accurate and fits perfectly with other components.

| Description | |

|---|---|

| General Tolerances | Metals : ISO 2768-m Plastics : ISO 2768-c |

| Precision Tolerances | RapidDirect can manufacture and inspect parts with strict tolerances according to your drawing specifications and GD&T annotations, including tolerances tighter than +/- 0.001 inches. |

| Min Wall Thickness | 0.5mm |

| Min End Mill Size | 0.5mm |

| Min Drill Size | 1mm |

| Maximum Part Size | CNC Milling: 4000×1500×600 mm CNC Turning: 200×500 mm |

| Minimum Part Size | CNC Milling: 5×5 ×5 mm CNC Turning: 2×2 mm |

| Production Volume | Prototoyping: 1-100 pcs Low volume: 101-10,000 pcs High volume: Above 10,001 pcs |

| Lead Time | 5 bussiness days for most projects. Delivery of simple parts can be as fast as 1 day. |

CNC Machining for Various Industries

Aerospace

Automotive

Automation

Medical Devices

Robotics

Consumer Products